Coolant for Plasma, MIG and TIG torches

Chemtex manufactures torch coolant antifreeze for use in all welder torch radiator circulation and re-circulation cooling systems. They cool the power cables, torches, even the welding power supply. Special welding coolants provide the best performance for welding systems. These coolants will also protect your system from freezing, when exposed to cold climates.

This Plasma coolant is specifically formulated and recommended for all plasma, MIG and TIG torches, as well as for all general industrial applications. Plasma-torch coolant also eliminates deposition of corrosive minerals, built up internally during the operation.

How Torch Coolants work?

Power leads generate the most heat in a plasma cutting system as they pull a huge amount of electrical current and generate a substantial amount of heat in a relatively small physical space. That heat released is absorbed by the coolant that flows around the copper cable running through the hoses.

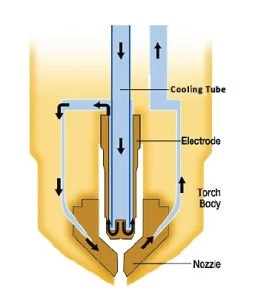

Torch/Welding Coolants cool down the torch, and prevent the electrode and nozzle from melting due to the high temperatures of the plasma arc. The cooling system is closed, viz., the coolant continually circulates through the system removing heat away from the affected components. After cooling the torch, the coolant is slightly warmer than it was when it entered the torch. It is usually the power leads. If the coolant is just pumped around in a closed circuit, it will keep getting warmer until it fails to cool the torch. To keep the coolant temperature low, it is pumped through either a cooler or a chiller.

Welding Coolant lubricates pump, liners, gasket and seal, reducing maintenance frequencies. The corrosion inhibitors protect iron, steel, aluminium, brass and copper components. The rust inhibitors extend its running life more than others coolant.

Power leads generate substantial heat in a plasma cutting system as they pull a huge amount of electrical current in a relatively small physical space. This released heat is absorbed by the coolant that flows around the copper cable running through the hoses.

Application Areas

- Heavy-duty Engines

- Marine Cooling Systems

- Mixed Fleet

- Stationary Engines

Chemtex Welding Coolants are non-volatile, non-hazardous, thermally stable with dielectric properties, making them suitable for plasma arc welding and tungsten inert gas welding systems.

Key Features and Benefits

- Improves cut quality and consistency

- Increases cutting speeds and material thickness capabilities

- Extends life of the torch

- Lessened starting problem of the torch

- Reduces electrical consumption

- Non foaming nature

- High stability, consistent performance

- Prevents corrosion and rust

- Eliminates need for coolant additives

- Maintenance free

Brand Names

Low electrical conductivity coolant designed for TIG applications