What is Morpholine?

Morpholine is an organic amine used as boiler corrosion inhibitor. It finds a variety of uses such as manufacturing of rubber accelerators, curing agents, cleaning agents, anti-rust agents, and surface-active agents. It contains both amine and ether groups, used in a wide range of applications. The amine group makes its base, its conjugate acid is called morpholinium, which appears as a colourless liquid with a fishlike smell.

In boiler water treatment, morpholine helps increase the pH of boiler feed water to protect the boiler against corrosion. It is used as boiler inhibitor intermediate available in the form of a colourless liquid.

How Does Morpholine Work?

Boilers are usually used in various industrial companies for their steam production capability. Ensure that such boiler systems are correctly going on and they work at optimum efficiency. To ensure an efficient process and quality steam creation capacity of the boiler system, the correct water condition must be maintained at all times. Heat exchange, steam protection, and corrosion protection are all necessary for boiler water treatment.

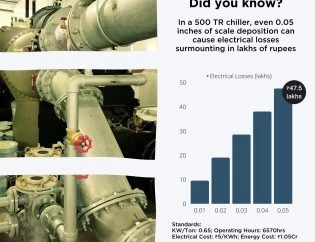

The efficiency of any boiler depends upon its capability of heat transfer. In a boiler system, all the contact surfaces between the fireside and steam side are made up of metals or metal combinators as metals are good conductors of heat. A large number of components can be dissolved in water as water is known as a universal solvent. Now the water used here is mostly untreated such as river water, tap water, municipal bores, etc. which has dissolved oxygen. It reacts with metal and forms metal oxide. These oxides can occur in corrosive reactions and can degrade the metallic property of the boiler system.

It can be accomplished by dosing selected chemicals for boiler water treatment into the feed water. The appropriate Boiler system will assist with keeping away from higher repair costs, poor quality of steam, and expensive maintenance fees because of scaling, consumption, and fouling of the heater and downstream apparatus. Continuous accumulation of salts and when it exceeds the solvency results in the formation of scales.

What are the Benefits of Using Morpholine as a Boiler Corrosion Inhibitor?

Benefits of Using Morpholine

- Prevents corrosion due to stress cracking

- Does not contribute to TDS

- Reduces blow-down requirement

- Compatible with other boiler water treatment chemicals

- Returns to the feed line with the condensate return raising the feed water pH

Should Use Morpholines for Your Boilers

Chemtex manufactures a range of boiler chemicals each tailor-made to meet desired end-uses. Morpholine is one of the extremely versatile compounds broadly as a boiler corrosion inhibitor in steam boiler systems.

Recent Posts

- What Swimming Pool Chemicals are essential for maintaining a clean and safe pool?

- Did you know that even a 2.5mm layer of dust over a solar panel surface can reduce its efficiency by 35%?

- The Impact of Descaling Chemicals on Industrial Operations: A Detailed Analysis

- How speciality chemicals play an important role in CIP process of Breweries & Microbreweries?

- Propylene glycol has many uses beyond just being an antifreeze. Discover some of them here!

- Chemicals for Boiler Feed Water

- Acid Inhibitor Chemicals for Mineral Acid Corrosion

- Engine Coolant Antifreeze Liquid

- Sulfamic Acid Descalant – How it Works, Where to Get

- Citric Acid Manufacturing Companies in India