Boiler feed water needs to be treated with chemicals in order to prevent corrosion and scale formation. It is important to add the correct chemicals to your feed water in order to ensure that it functions correctly and produces heated water.

Boiler feed water chemistry

Porous forms of salts such as Calcium, Magnesium and high carbonaceous deposits precipitate and form dense uniform pitting and scaling over the boiler surfaces. With the feedwater, the dissolved solids and impurities begin to precipitate at the base, with a continuous accumulation.

Along with dissolved salts, there are also some suspended solids in that get precipitated as sludge. These are not hard as compared to scales, but if overlooked, gets hardened due to continuous heating in the boiler.

Feed water characteristics – Scales

- Carbonate deposits, granular and porous form dense and uniform pitting and scaling

- Sulphate deposits, crystalline fine particles harder and denser than regular carbonate deposits

- Hard and difficult to remove silica deposits, extremely small, forms a dense and impervious scaling

- Iron (Fe) deposits

The Basics of Adding Boiler Chemicals:

There are a few basic things you need to know in order to add boiler feed water chemicals correctly. These include:

- Chemical type: There are many different types of feed water chemicals available on the market. Consult with a professional before making a purchase.

- Quantity: You will need to add a certain amount of chemical per gallon of water in your boiler system. This quantity varies depending on the type of chemical you are using. Always follow the instructions provided by the manufacturer closely.

- Location of Chemical Addition: Most boilers have a designated spot where the chemical addition point is located. It is important to add the chemical here in order achieve optimal results. Consult with a professional if you are unsure about where this point is located on your boiler system.

Key Benefits:

There are many benefits of adding proper levels of boiler feed water chemicals to your system. Some key benefits include:

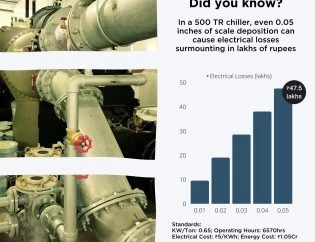

- Increased Efficiency: When you properly maintain your boiler system with added chemicals, it runs more efficiently than ever before. This reduces energy consumption and saves money, time and labour.

- Reduced Corrosion: Boiler feed water chemical additives protect against corrosion, which can damage your system over time. By using them, you can extend the life of your boiler and prevent costly repairs from occurring down the road.

- Improved Performance: Properly maintained boilers perform better than those that are not. When all components are working together as they should, your boiler system will function at peak performance levels.

Chemtex Boiler Feed Water Chemicals

Boiler water treatment and conditioning of feed water to maintain optimal heat exchange, and protection of the boilers. If you want your boiler to remain in good condition and be as efficient as possible, it’s important that the water remains free from impurities, which means that water treatment will be necessary.

There are two methods that can be used for the chemical treatment of boiler feed water, which include external treatment and internal treatment.

Both of these processes rely on the conditioning process, which essentially counteracts the hardness in water by introducing softening agents to the water. Once these agents have been placed in the water, most of the minerals, contaminants, and chemicals within the water should be altered or removed completely.

Chemtex Speciality Limited has over five decades of experience in manufacturing boiler chemicals and consultation. With a wide portfolio to choose from to effectively counter or prevent mineral scales, metal oxides, hard deposits of water scale, iron oxides, oily contaminants, sludge, lime, and greasy deposits on the boiler surfaces.

Using these chemicals regularly ensures the protection of the system metallurgy, providing a long service life for the boiler system. We formulate a range of boiler chemicals to ensure the safety of the boiler and feed water. This formulation eliminates mineral scales, metal oxides, sludge, and other depositions, prevents corrosion caused by oxidation, maintains pH values, and removed oxygen instantly.

Recent Posts

- The Impact of Descaling Chemicals on Industrial Operations: A Detailed Analysis

- How speciality chemicals play an important role in CIP process of Breweries & Microbreweries?

- Propylene glycol has many uses beyond just being an antifreeze. Discover some of them here!

- Chemicals for Boiler Feed Water

- Acid Inhibitor Chemicals for Mineral Acid Corrosion

- Engine Coolant Antifreeze Liquid

- Sulfamic Acid Descalant – How it Works, Where to Get

- Citric Acid Manufacturing Companies in India

- Why You Should Use Morpholine for Your Boilers

- 6 Types of Construction Chemicals to ensure the right cement mix

Categories

- Cleaning & Disinfectant Chemicals (13)

- Energy Chemicals (3)

- Heat Transfer Fluids (3)

- Mostbet (1)

- Performance Chemicals (8)

- Uncategorized (4)

- Water Treatment Chemicals (6)