As the source of power for cars, engines get extremely hot. They produce an immense amount of heat of it requires one-third to and the rest if uncontrolled will destroy the engine, and must be expelled to prevent overheating and failures. Without proper protection, an engine can wear down and even melt, which can cost huge money to replace.

The first coolant was pure water.

Pure water freezes at 0°C and boils at 100°C. Outside of this range, water loses its functionality, turning into steam at one end and expanding as ice at the other. Both forms present a list of issues and cannot transfer heat effectively. To do the job properly, pure water was not enough and something was needed to be added.

Engine coolant antifreeze

Ethylene Glycol (EG) is one of the earliest antifreezes, circa 1856. It has a boiling point of 197°C and freezes at (-)13°C, allowing a wider range of functionality. By combining equal parts water and EG, the functional range of coolant expands to -36°C to 129°C while retaining the original heat transfer property.

How does a coolant work?

Engine coolant is used in conjunction with a liquid cooling system, made up of

- Coolant pump which circulates the coolant throughout the system

- The radiator assembly conducts heat away from the coolant

- Radiator hoses connecting all the parts of the cooling system

- Thermostat controlling the coolant temperature.

The coolant inside the cooling system improvises the cooling efficiency. When the engine is running, the coolant continuously circulates through the engine and returns through the radiator. Coolant is pumped through small channels in the engine block and absorbs the excess heat to control the engine temperature. When antifreeze liquid is diluted with water, it also helps lubricate the engine’s internal components.

Engine coolant antifreeze absorbs the heat from the engine and then disperses it into the air through the radiator. It also protects the engine from rusting, decreases the freezing temperature, and increasing the boiling temperature of the fluid that flows around the engine.

What is engine coolant made of?

Automotive coolants consist of a mixture of antifreeze with additive packages and water. These are designed to prevent corrosion, and rusting.

The added inhibitors can be classified as Inorganic Acid Technology (IAT), Organic Acid Technology (OAT) or Hybrid Organic Acid Technology (HOAT).

An ideal coolant should provide:

- Prevent freezing in cold temperatures

- Remove corrosion and rust of metal parts in cooling circuit and engine

- Prevent the coolant from boiling in hot temperatures

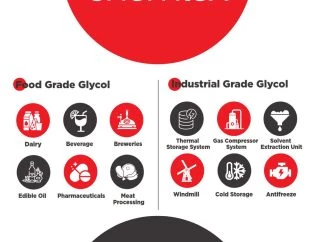

Chemtex manufactures glycol-based coolant antifreeze liquid used as an alternative to water-based coolants. Chemtex engine coolants come in Tropical Car Coolant, and Extended Life Coolant (ELC).

These are inhibited with anti-corrosion, anti-scaling, and anti-microbial properties, protecting the engines from the adverse effects of extremely low and high temperatures. That protects your engines from cracking and increased pressure. They also prevent buildup of scale and sludge, and preventing radiator contamination and blockage.

Recent Posts

- The Impact of Descaling Chemicals on Industrial Operations: A Detailed Analysis

- How speciality chemicals play an important role in CIP process of Breweries & Microbreweries?

- Propylene glycol has many uses beyond just being an antifreeze. Discover some of them here!

- Chemicals for Boiler Feed Water

- Acid Inhibitor Chemicals for Mineral Acid Corrosion

- Engine Coolant Antifreeze Liquid

- Sulfamic Acid Descalant – How it Works, Where to Get

- Citric Acid Manufacturing Companies in India

- Why You Should Use Morpholine for Your Boilers

- 6 Types of Construction Chemicals to ensure the right cement mix

Categories

- Cleaning & Disinfectant Chemicals (13)

- Energy Chemicals (3)

- Heat Transfer Fluids (3)

- Mostbet (1)

- Performance Chemicals (8)

- Uncategorized (4)

- Water Treatment Chemicals (6)