Mitigating Industrial Acid Corrosion

Industries like oilfields and processing facilities have huge involvement in steel and iron, zinc, and ferrous alloys. Proper maintenance is essential as the maximum utilization of their by-products like storage tanks, chimneys, building structures, pipelines, and machinery are related to broad-spectrum applications. In heavy industry, metals are subject to corrosion caused by acids, and bases and causing metal loss.

What is Acid Corrosion?

Corrosion is generally a process by which any ferrous metals comprises iron, different alloying elements such as manganese, sulphur, copper, phosphorus, carbon, nickel, silicon, chromium, aluminium), and impurities such as phosphides, sulphides etc.

How does Corrosion Occur?

Corrosion can cause the deterioration of materials by chemical interaction with their environment. Corrosion is a result when the hydrogen ion concentration reacts with the electrons of metals, damaging operational equipment, and structures. Some of the hydrogen ions won’t be able to form a hydrogen molecule, those ion gets induced in the metallic body through absorption as a hydrogen ion. Acidic Corrosion causes wear and tear of material mainly by acidic components which can be prevented by the application of the right proportionated inhibitor.

Why does metal get corroded?

Steel and iron are mainly used in many industries for their excellent mechanical characteristics and cheaper cost. Various industry processes use acidic solutions widely for their low cost, some of the critical fields of the application being acid pickling of steel, ore production and oil well acidification, chemical cleaning and processing, etc. These acidic solutions react with metallic surfaces and cause the deterioration of materials.

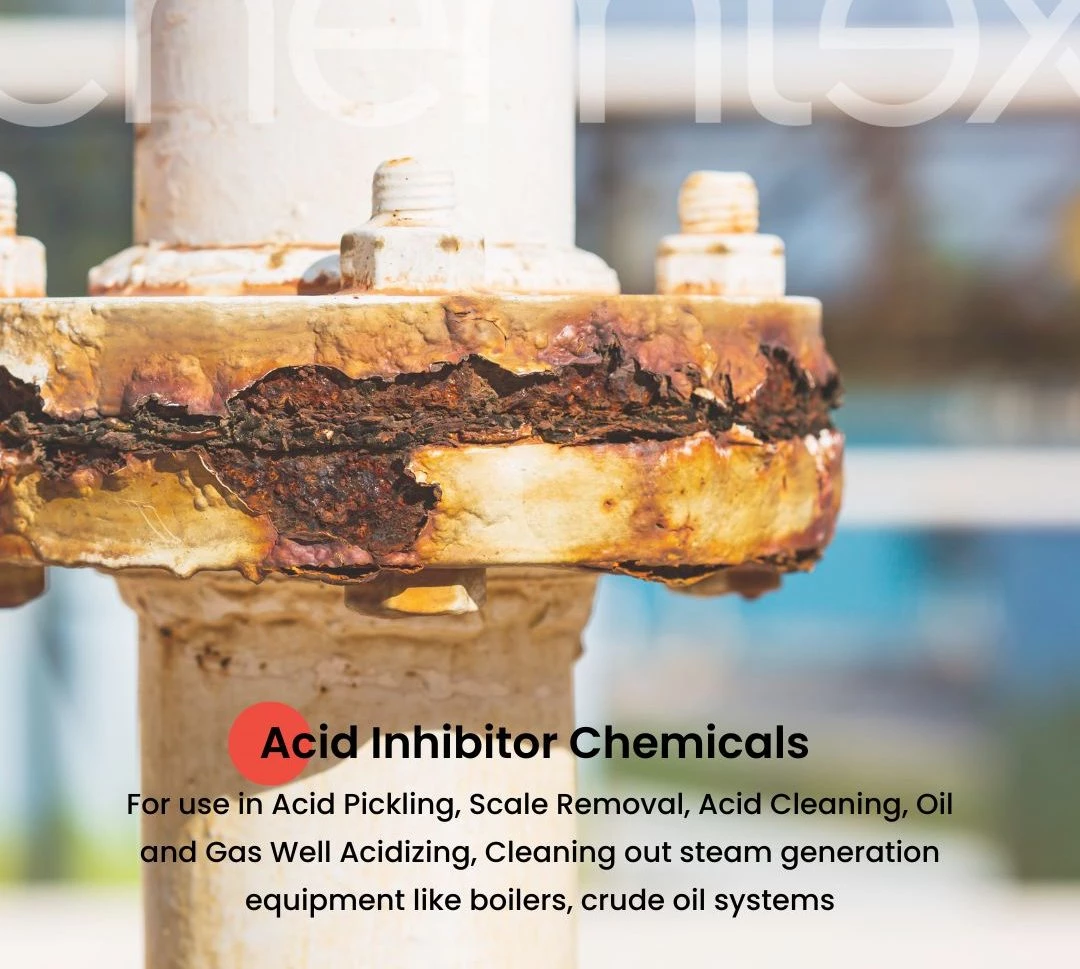

Acid Inhibitor Chemicals

Acid Inhibitor is a speciality chemical blend formulated to combat such acidic solutions. It contains a highly effective blend of surfactants, solvents, and dispersants that prevent corrosion even at high temperatures. Inhibitors are chemicals that react with a metallic surface or the environment to which this surface is exposed, by adsorbing themselves on the metallic surface, protecting the surface by forming a film.

Benefits of using Acid Inhibitors:

- Efficiency to inhibit corrosion from the metal surface

- Effectively remove scale from the corroded metal surface

- Economical & not labour-intensive

Chemtex Speciality Limited manufactures manufactures superior-quality acid corrosion inhibitors for preventing any type of corrosive reaction between metal ions and harsh gases. Our formulations inhibit corrosion and pitting, during hot treatment acidification on production tubing, through the formation of a protective layer over the surface. These inhibitors are used to combat the corrosive attack on metallic elements. It is thermally stable, and well-compatible with any other chemicals. This formulation can be used for cleaning out steam generation equipment like boilers, crude oil systems, oil pipelines, and oil wells.

Key features and benefits

- Effective inhibition from corrosive attacks

- Thermally stable

- Prevents sweet and sour corrosion rate

- High temperature & strong acid stability

- Cost-effective dosage

- Compatible with all types of metals and other common additives.

- Environment Friendly

Recent Posts

- The Impact of Descaling Chemicals on Industrial Operations: A Detailed Analysis

- How speciality chemicals play an important role in CIP process of Breweries & Microbreweries?

- Propylene glycol has many uses beyond just being an antifreeze. Discover some of them here!

- Chemicals for Boiler Feed Water

- Acid Inhibitor Chemicals for Mineral Acid Corrosion

- Engine Coolant Antifreeze Liquid

- Sulfamic Acid Descalant – How it Works, Where to Get

- Citric Acid Manufacturing Companies in India

- Why You Should Use Morpholine for Your Boilers

- 6 Types of Construction Chemicals to ensure the right cement mix

Categories

- Cleaning & Disinfectant Chemicals (13)

- Energy Chemicals (3)

- Heat Transfer Fluids (3)

- Mostbet (1)

- Performance Chemicals (8)

- Uncategorized (4)

- Water Treatment Chemicals (6)